In the pursuit of creating focused living or working spaces, the importance of acoustic insulation cannot be overstated. Unwanted noise can disrupt concentration, impact productivity, and diminish the overall quality of our surroundings. This is where Acoustic Foam emerges as a practical and efficient solution.

At Delta Rubber Limited, we recognize the significance of achieving peace and quiet in your space. In this blog post, we’ll delve into the essential role of acoustic insulation and introduce our Acoustic Foam – a reliable, straightforward, and effective means to address the challenges of sound control. We’ll explore the dimensions, pricing, and customization options that make our Acoustic Foam a standout solution for enhancing your acoustic environment.

Understanding Acoustic Insulation

Acoustic insulation plays a pivotal role in creating comfortable and peaceful environments, shielding spaces from unwanted noise and disturbances. Whether you’re looking to enhance the tranquility of your home, office, or recording studio, a fundamental grasp of acoustic insulation is crucial. Let’s delve into the essentials.

What is Acoustic Insulation?

Acoustic insulation involves the implementation of materials and techniques designed to minimize the transmission of sound from one area to another. It acts as a barrier, preventing the entry or exit of sound waves and contributing to a quieter, more serene atmosphere.

The Science of Sound

To comprehend the significance of acoustic insulation, it’s essential to understand the science of sound. Sound travels in waves, and when these waves encounter obstacles, they can be absorbed, reflected, or transmitted. Acoustic insulation primarily focuses on impeding the transmission of sound waves, ensuring that they don’t penetrate or escape a designated space.

The Need for Effective Acoustic Insulation

In various settings, from residential homes to commercial offices and entertainment spaces, the need for effective acoustic insulation is evident. Excessive noise can lead to stress, decreased productivity, and disrupted concentration. Acoustic insulation provides a practical solution to these issues, creating environments that promote well-being and focus.

How Acoustic Insulation Works

Acoustic insulation materials, such as fiberglass, foam, and mass-loaded vinyl, disrupt the transmission of sound waves through various mechanisms. They absorb sound energy, convert it into heat, or reflect it away, preventing it from reaching the other side of the barrier.

In the realm of acoustic insulation solutions, one standout product is the Acoustic Foam Sheet. Engineered for optimal sound absorption, it effectively reduces reverberation and controls echoes, making it an excellent choice for a range of applications.

In the next sections, we’ll explore the specific benefits of acoustic insulation, the various types available, and how the Acoustic Foam Sheet stands out as a versatile and efficient solution for soundproofing. Join us on this journey to master the art of acoustic insulation and create spaces that resonate with tranquility.

Acoustic Foam Sheet Overview

Acoustic Foam is a versatile and effective solution for sound control, specifically designed to attenuate a broad spectrum of airborne sound frequencies. As a pivotal component in creating tranquil and productive spaces, Acoustic Foam proves indispensable for those seeking effective noise reduction. Here’s a detailed exploration of its characteristics and applications.

Open-Cell Composition for Comprehensive Sound Absorption

Acoustic Foam’s open-cell structure is fundamental to its success in mitigating sound. This unique composition allows the foam to capture and dissipate sound waves across a broad spectrum of frequencies. By addressing a wide range of tones, it ensures a comprehensive and effective approach to sound control.

General Purpose Adaptability for Varied Settings

Versatility is a hallmark of Acoustic Foam, making it a go-to choice for a myriad of environments. Its general-purpose application means it seamlessly integrates into residential, commercial, and creative spaces. From homes and offices to recording studios, this adaptability positions Acoustic Foam as a versatile solution for controlling unwanted noise.

BS476 Class 0 Fire Retardancy

Safety is paramount in any insulation material, and Acoustic Foam doesn’t disappoint. Complying with BS476 Class 0 fire retardancy requirements, it not only excels in sound absorption but also prioritizes fire safety. This dual functionality enhances its suitability for a range of applications, assuring users of both effective sound insulation and adherence to essential safety standards.

Varied Applications for Controlled Acoustics:

Acoustic Foam’s effectiveness extends beyond the traditional. Its application spans various scenarios, including insulating homes for a more peaceful living experience and creating sound-sensitive environments in professional settings. Whether used in a home theater for improved audio quality or in an office to enhance concentration, Acoustic Foam consistently delivers on the promise of controlled acoustics.

In summary, Acoustic Foam stands as an essential tool in crafting spaces with effective acoustic insulation. Its ability to absorb sound comprehensively, adapt to diverse settings, prioritise safety, and cater to various applications makes it an indispensable element in the pursuit of acoustic insulation benefits.

Acoustic Foam Installation Guide

Installing Acoustic Foam is a straightforward process that can significantly enhance the sound insulation of your space. Whether you’ve opted for the convenience of our Acoustic Foam with Self-Adhesive Backing or the versatility of plain Acoustic Foam, here’s a comprehensive guide to ensure a hassle-free installation.

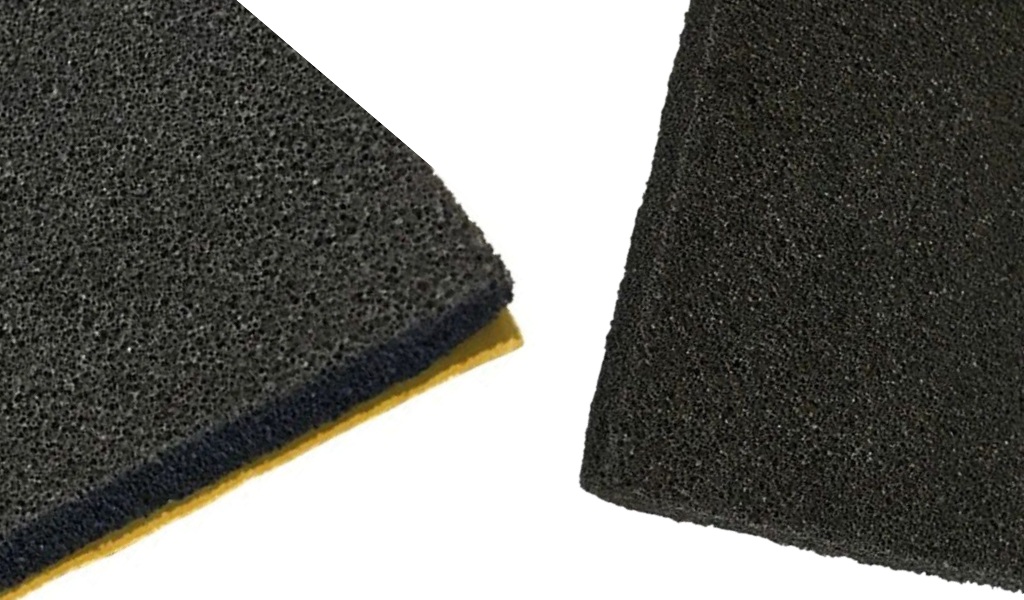

Acoustic Foam with Self-Adhesive Backing

- Clean and Prep Surfaces: Before applying the Acoustic Foam, ensure that the surfaces are clean and free of dust or debris. This step is crucial for the adhesive to bond effectively.

- Peel Backing: The Acoustic Foam with Self-Adhesive Backing is designed for easy installation. Simply peel off the backing to expose the adhesive side.

- Stick in Place: Carefully position the foam on the desired surface, pressing firmly to ensure proper adhesion. Start from one corner and smooth out any air bubbles as you adhere the foam.

- Allow for Adhesion Time: After installation, allow some time for the adhesive to bond securely to the surface. This ensures the longevity and effectiveness of the Acoustic Foam.

Plain Acoustic Foam

- Choose the Right Adhesive: When installing plain Acoustic Foam, you’ll need a suitable adhesive. Consider using adhesive sprays or special foam adhesives that are safe for the material.

- Mark Placement: Before applying adhesive, mark the placement of the foam on the surface. This ensures a precise installation and helps you align the foam correctly.

- Apply Adhesive: Following the product instructions, apply the adhesive to the back of the foam. Be sure to cover the edges and corners thoroughly.

- Press and Hold: Press the foam onto the surface, holding it in place for a few moments to allow the adhesive to take hold. Applying firm, even pressure helps ensure a secure bond.

- Allow for Drying Time: Similar to the self-adhesive option, allow sufficient drying time for the adhesive to set and the foam to adhere securely to the surface.

Where to Buy Acoustic Foam for Acoustic Insulation

Delta Rubber Limited is your go-to destination for high-quality Acoustic Foam designed to elevate your soundproofing endeavors. As a leading provider in the industry, we pride ourselves on offering solutions that combine effectiveness, convenience, and affordability.

When it comes to tailoring your Acoustic Foam to your specific needs, Delta Rubber Limited provides a variety of options. Our Acoustic Foam sheets come in standard sizes of 2 meters x 1 meter, ensuring flexibility for various applications. You can choose from thicknesses ranging from 6mm to 50mm, catering to the diverse requirements of your soundproofing project. Additionally, we offer the convenience of self-adhesive backing or the versatility of plain sheets, giving you the freedom to choose the installation method that suits your preferences.

At Delta Rubber Limited, we understand the importance of cost-effective solutions. Our pricing starts as low as £31.92 ex vat for plain Acoustic Foam and £42 ex vat for the self-adhesive variant. For larger projects, we provide generous discounts, making quality soundproofing accessible for all. We prioritize efficiency, offering next working day delivery under most circumstances. This ensures you can commence your project promptly without unnecessary delays.

To further tailor your Acoustic Foam to your unique project, we offer bespoke cutting services. Utilizing our state-of-the-art laser-guided CNC cutting machine, we can cut the foam into any shape or size you desire. This customization ensures a seamless fit and maximizes the effectiveness of your soundproofing efforts. Please contact us for bespoke cutting services.