Gasket Digitising & Scribing

We offer in-house gasket digitising and scribing services using advanced CNC machinery. From recreating damaged or discontinued gaskets to marking parts with unique reference numbers, our technology delivers fast, accurate results tailored to your project.

Innovative Addition To

Our Gasket Production

Looking to restore or identify a gasket for your project? Click below to contact our team and find out how our digitising and scribing services can help.

GASKET DIGITISATION

How Does Gasket Digitising Work?

Our gasket digitisation process begins by capturing a high-resolution image of your original or damaged gasket using precision imaging equipment. This image is then converted into an editable CAD file, allowing our team to recreate, enhance, or modify the design as needed.

Once approved, the digital file is used for accurate, repeatable production in your chosen gasket material. Whether you need a one-off replacement or a high-volume run, this process ensures consistent quality, reduced waste, and cost-effective manufacturing.

GASKET SCRIBING

How Does Gasket Scribing Work?

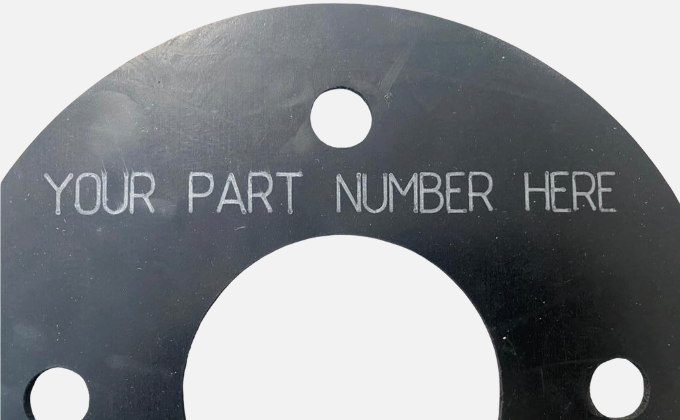

Gasket scribing uses our advanced CNC machinery to digitally mark each gasket during production with a part number, reference code, or customer-specific identifier. This process allows for easy identification, sorting, and traceability—especially useful in large-scale or repeat orders.

The marking is integrated into the cutting process, ensuring accuracy without compromising the gasket’s performance or integrity. It’s a smart solution for improving workflow, stock control, and component management across various industries.

Contact A Member

Of Our Team Today

Get in touch with us today! Our friendly and professional team is always ready to offer expert advice tailored to your needs. Whether you’re looking for product support or a bespoke quotation, we’re here to support you at every step of your project.